ABOUT US

Who we are. Company History. Mission, Vision, and Values. Visitor information.

About Moses Lake Industries

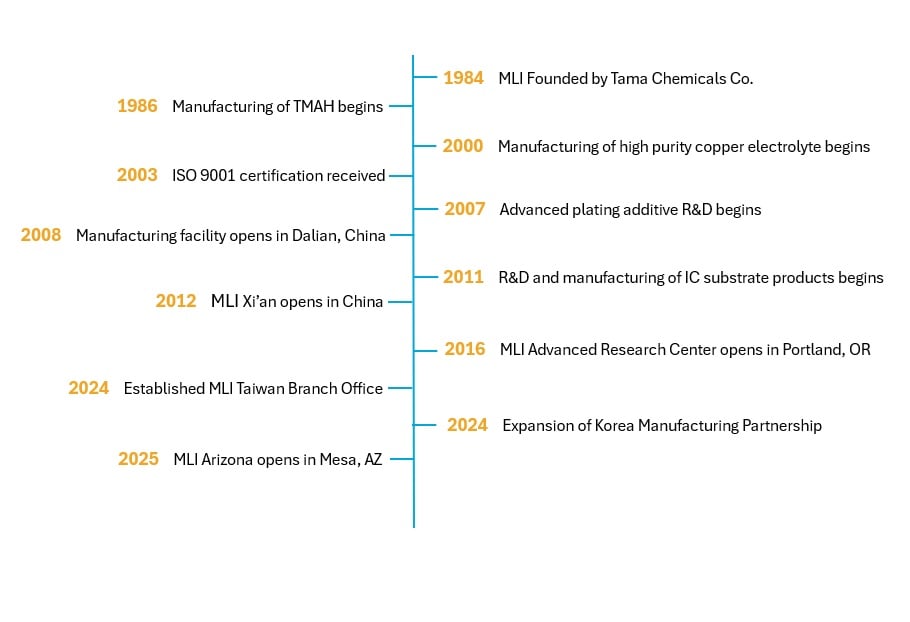

Founded in 1984 as a wholly owned subsidiary of Tama Chemicals, Moses Lake Industries (MLI) has become a trusted global supplier of high-performance chemical solutions for the semiconductor industry. With a deep commitment to customer success and continuous innovation, we deliver ultra-high-purity products that enable next-generation technologies and support the world’s leading chip manufacturers.

Mission

We develop and manufacture high-quality, leading-edge chemistries, while providing superior customer service and strengthening our team and communities for future generations.

Vision

MLI’s commitment to Innovative, Operational, and Financial Excellence are critical to meeting our mission.

Innovative Excellence – MLI was started 40 years ago based on a single product. Through our commitment to innovation, understanding of the market, and listening to our customers, we have grown our portfolio to over 1,000 products. We believe our focus on innovation is why our customers choose to partner with MLI.

Operational Excellence – MLI has grown our operational capabilities to keep pace with our innovative growth. We have developed a quality operating system that has led to a continuously improving production process. We believe that our in-house operational capabilities are the reason we are able to meet the evolving expectations of our customers.

Financial Excellence – MLI has become a very complex business with plants around the world. We work very hard to understand the cost to source raw materials, produce world-class products, and deliver. We believe that our focus on understanding and reducing our costs is the reason we can offer world-class products at cost-competitive prices.

Values

These values have led to our success over the past 40 years and will be a critical part of our success going forward.

- Safety

- Integrity

- Collaboration

- Ownership

- Sustainability

- Service

Timeline

Quality

A Comprehensive, Integrated Approach

Every individual at MLI is responsible for quality and continuous improvement; everyone is empowered to identify risks, concerns and issues effecting quality and safety. Systematic training and recertification of our staff ensure consistent awareness of MLI’s Quality Operating System, and compliance with procedures and requirements.

Our Quality Management System provides a consistent and coordinated approach to ensure and improve quality through every step of development, manufacturing, delivery and customer support.

Communication and close interaction with our customers is key to identifying needs and developing solutions that will meet and exceed expectations. We build strong relationships with our customers by listening, working collaboratively and acting as partners in innovation.

Issue prevention via Failure Mode and Effects Analysis (FMEA) is an integral part of our product and process design and has informed and continues to shape our Quality Management System:

Raw Material Sourcing – To ensure the highest quality and consistency, we manufacture as much of our our own raw material as possible. Raw material not produced in-house undergoes rigorous acceptance testing prior to use.

Manufacturing Systems Control– Our in-house experts design, build and manage our infrastructure and manufacturing systems. This level of control allows us to ensure the highest quality and consistency through multiple facilities. It also facilitates quick response to the evolving needs of our customers.

Analysis and Monitoring – Advanced analytical devices provide continuous real time monitoring and analysis of production, allowing for immediate in-line corrective response. Solicitation of customer feedback as well regular internal audits and self-assessment of processes support continuous improvement.

Packaging – We maintain strict packaging specifications, cleaning methodologies and filling preparation procedures to eliminate sources of contamination. A Certificate of Analysis, with complete analytical results, is provided with each product shipment.

Delivery – Warehouse and shipping conditions and procedures are rigorously controlled to ensure products are consistently received on time, damage-free and within temperature specification.

Customer Support – Quality and consistency is critical in our products, and crucial in our personal interactions, as well. Our management team, scientists, sales staff and accounting and billing department aim to provide unsurpassed responsiveness and customer service.

Purchase Order & Conditions

Click here for our Purchase Order Standard Terms and Conditions for Purchase Orders issued on or after October 01, 2013

Click here for our Purchase Order Standard Terms and Conditions for Purchase Orders issued on or after April 18, 2014

Click here for our Purchase Order Standard Terms and Conditions for Purchase Orders issued on or after January 04, 2017

Click here for our Purchase Order Standard Terms and Conditions for Purchase Orders issued on or after February 15th, 2019

Click here for our Purchase Order Standard Terms and Conditions for Purchase Orders issued on or after March 17th, 2022

Click here for our Purchase Order Standard Terms and Conditions for MLDCI-issued Purchase Orders on or after July 6th, 2023

Click here for our Purchase Order Standard Terms and Conditions for MLXCI-issued Purchase Orders on or after July 6th, 2023

Click here for our Purchase Order Standard Terms and Conditions for Purchase Orders issued on or after March 15th, 2024

Visitor Information & Safety Quiz

If you are planning to visit Moses Lake Industries’ Global Headquarters in Moses Lake, Washington, please take a moment to watch the Visitor Safety video below and read through the linked Visitor Safety Information.

After watching the video, review our written safety orientation and print out a copy of the Visitor Safety Orientation Quiz, found on the last page. Visitors are required to present a signed copy of the quiz upon entry.

We not only provide Pure Solutions for our customers, but also for our PEOPLE

Our culture is about belonging to a team and a global community who genuinely care and are committed to doing our best work for one another. It’s no secret, the power of our people is key to our success. We know it. They know it.